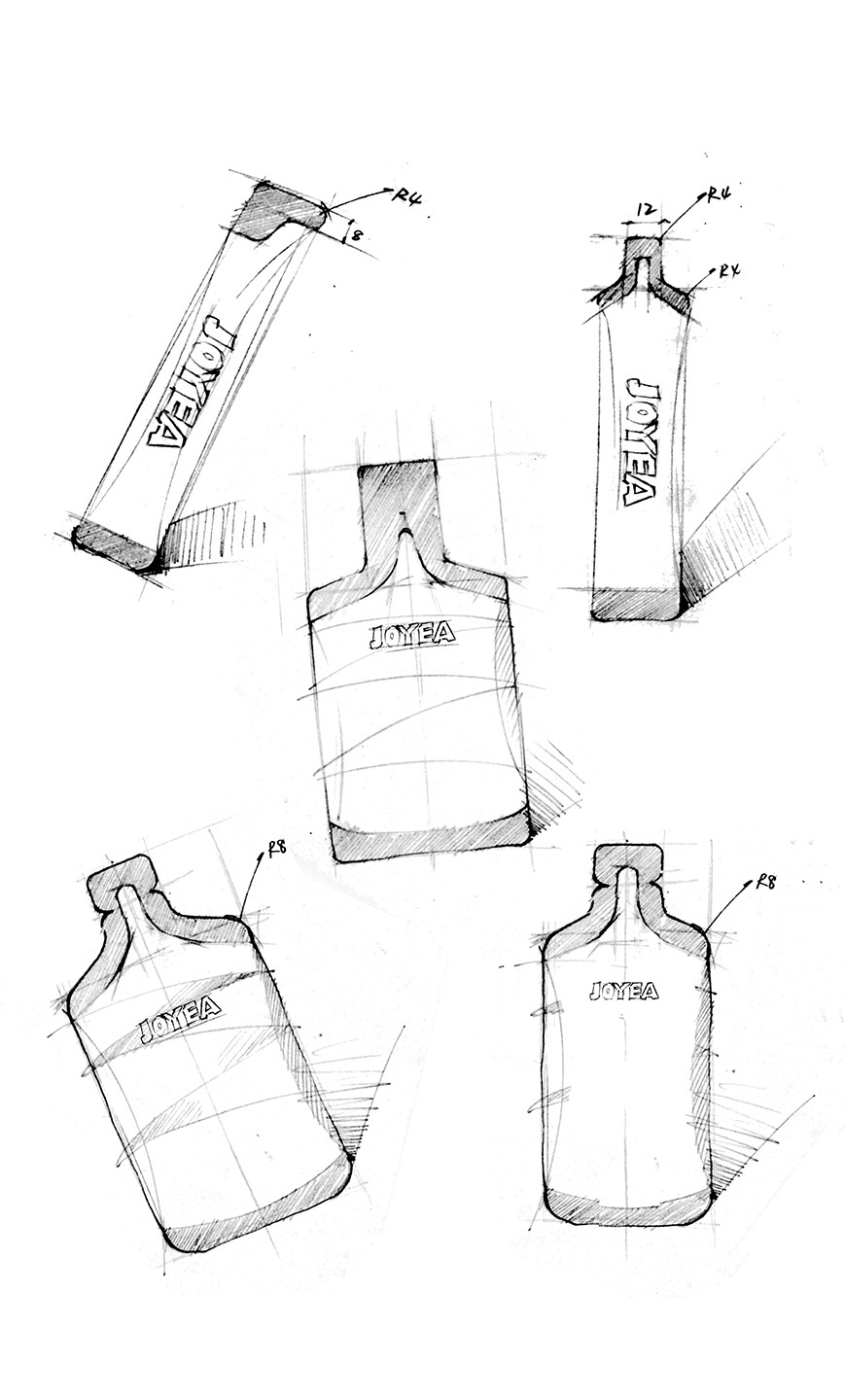

Product Conceptual design

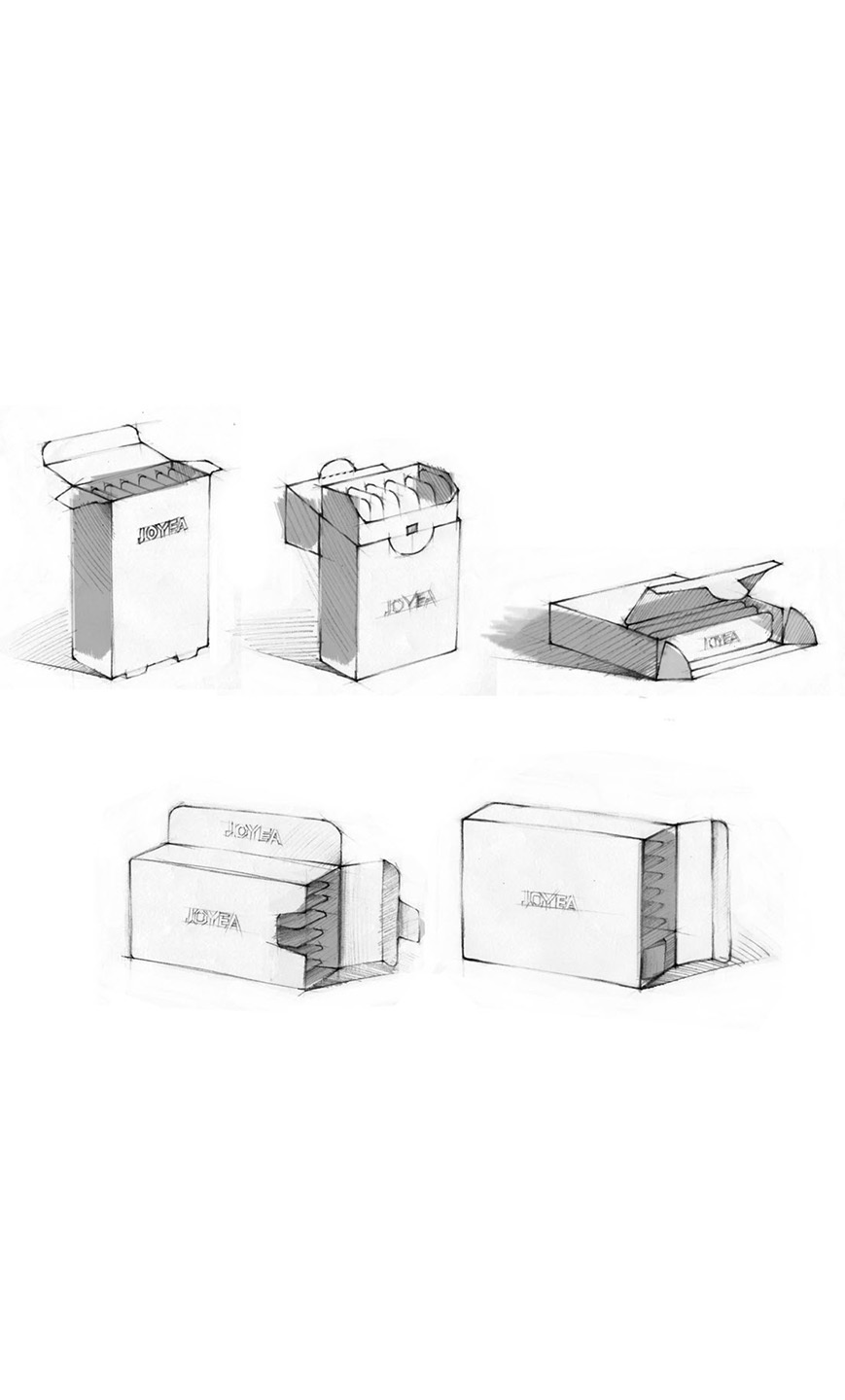

Packaging Design

Sample Evaluation

ODM&OEM

Test & Design

Analysis Laboratory

Test Laboratory

Packaging Solution Design

Product Delivery

Design Review

Participate in Installation

Training

Remote FAT

SAT

After sale Service

Specilist Role

Remote Assistance(24/7 online)

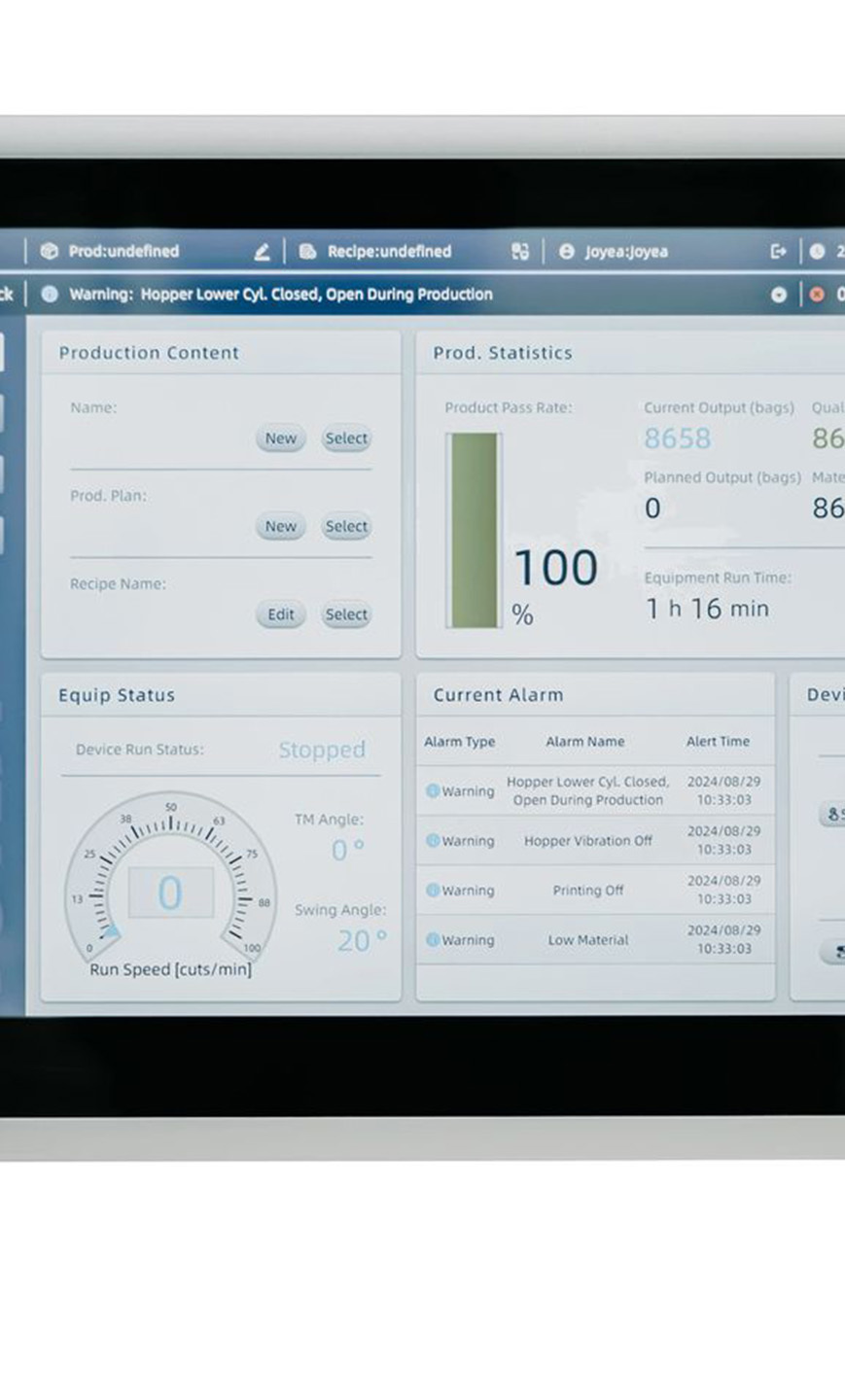

Digitization

Digitization

Packaging Design

Sample Evaluation

ODM&OEM

Analysis Laboratory

Test Laboratory

Packaging Solution Design

Design Review

Participate in Installation

Training

Remote FAT

SAT

Specilist Role

Remote Assistance(24/7 online)

Digitization

Packaging Design

We are involved in the early stages of customer product concepts. According to customers' product form, market positioning, filling capacity and packaging needs, we combine our experienced design team with customers to provide customers with exclusive and personalized suggestions and design solutions.

Sample Evaluation

We can make some samples for customers to experience and evaluate according to customers' product and packaging design requirements.

ODM&OEM

You can also choose from our foundry services. Test the market response through small batch production verification by our qualified foundries, accelerate the speed of product to market and reduce capital investment.

Analysis Laboratory

We are equipped with a variety of professional instruments, which can carry out scientific and accurate testing of product, packaging materials, packaging quality, etc. ● Powder characteristic (Angle of Repose and Fall,Uniformity,Flowability Index etc) ● Liquid characteristic(viscosity,PH,surface tension etc) ● Film characteristic(Friction coefficient,stretch rate etc) ● Package quality(Airtightness,CAN Overlap percent,Tightness rate etc)

Test Laboratory

By analyzing data from the lab. We can find the most suitable technical solution from thousands of accumulated cases, and give a trusted technical indicator commitment by simulating the operating environment of the customer's site in the test laboratory, controlling temperature, humidity, and using equipment testing of key components consistent with the final delivery equipment.

Packaging Solution Design

We will help customers to consider the overall, comprehensive capacity requirements, future specifications, sites, return on investment, operating costs and other aspects to design the best solution, so that equipment continue to maximize the value of customers.

Design Review

We design in three dimensions and invite the user to participate in the design review during the design phase. Ensure that all designs meet DQ requirements.

Participate in Installation

In the stage of equipment assembly, customers can come to our factory to participate in the installation process, forming a deeper understanding of the principle, structure and maintenance of the machine.

Training

We will invite customer operators to our factory after the completion of product commissioning, trained by professionals, and issued equipment operation certificates to qualified personnel.

Remote FAT

For customers who are inconvenient to come to our factory for FAT, we can also provide remote FAT to complete acceptance through online audio and video interaction, improve work efficiency and reduce acceptance costs.

SAT

We help customers complete on-site installation, commissioning, trial operation, and track production for a period of time to ensure that customers can operate the equipment independently. And assist customers to complete the 4Q verification work on site.

Specilist Role

We will designate a special person called specilist for each customer, who is responsible for all the information contact with the customer. And regular visits to the customer site, timely listening to customer feedback, to ensure customer satisfaction.

Remote Assistance(24/7 online)

Due to the help of modern communication technology, we can be online 24/7 to provide customers with real-time remote assistance services, including: ● Remote real-time support for operators to operate equipment ● Timely handling of emergency situations ● Improve problem solving efficiency

Digitization

Since Joyea's inception, there has been a consistent focus on the application of digitalization in business operations and products. We provide a wealth of digital system capabilities for production lines and equipment. Includes: ● Provide equipment digital interface, to facilitate the customer's MES system ● Help customer record the operating status of the system in real time, as the basis for problem diagnosis, and formulate the best solution ● Provide LIS(Line integrate system) to provide customers with operation data integration and production reporting functions of Joyea production lines. ● Remote assistance system to help customers quickly deal with on-site problems.

Jiangsu Yizi United Zhizao Co., Ltd.

Contact Us

Telephone:+86 13952896255/15952948898

E-mail:IBD@joyeagroup.com

Website:www.joyeagroup.com

Address: Wisdom Park,111# Qianjin Road,Development Zone,Danyang,Jiangsu Province,China